This range gives us a maximum and minimum permissible value of shaft diameter as 70.00 mm and 69.95 mm respectively.Īn advantage of using unilateral tolerance is the ease with which we can inspect it. If we can allow a maximum deviation of 0.05 mm, we will set the tolerance range for this shaft as 70 +0.00 /-0.05 mm. To prevent this, we use unilateral tolerances for such parts. This would increase wastage and turnaround time. Thus, we cannot use the shafts manufactured with a diameter greater than 70 mm. If the shaft’s diameter exceeds 70mm even by a small amount, it will not fit into the hole. In other words, we allow deviation on only one side of the nominal value.Ĭonsider a shaft of diameter 70mm that needs to fit into a hole of the same size. In unilateral tolerance, we define the range of values in one direction only. The corresponding dimension of the manufactured components should lie between these two points for use in the assembly.įor example, if the limit tolerance for a dimension is defined as 12…12.5 mm, the final value must lie between these two boundaries. We express the limit tolerance as a minimum and maximum permissible value for a dimension.

Din tolerance chart iso#

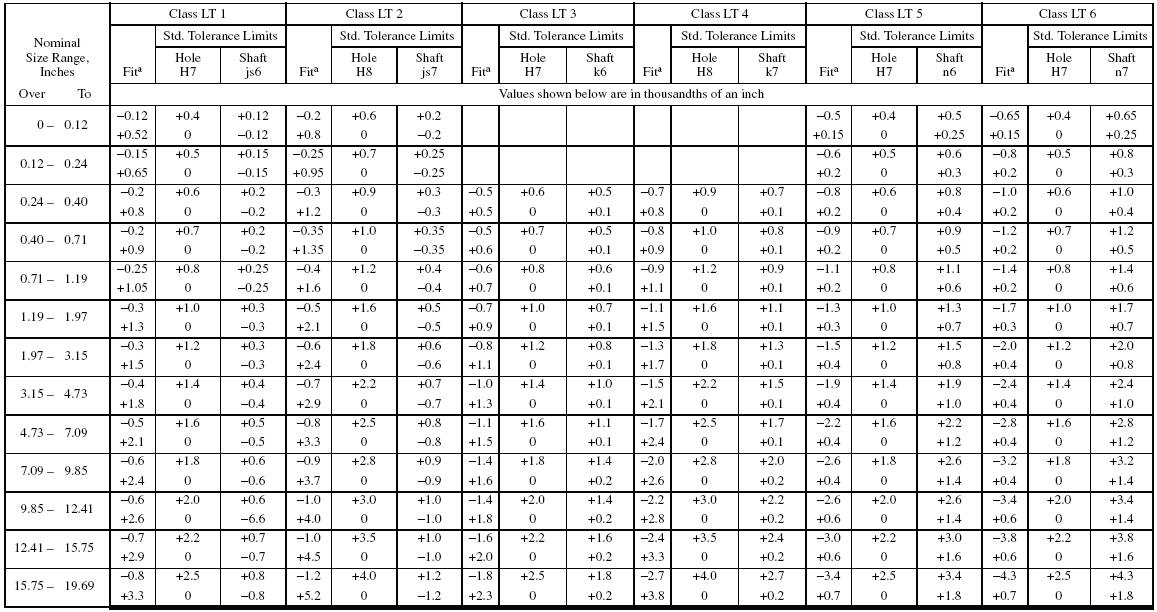

The range for each tolerance limit for a particular dimension bracket is based on International Standards (EN 20286, JIS B 0401, ISO 286, ISO 1829, ISO 2768, ANSI B4.1, ANSI B4.2). These classes are arranged into a chart that separates the different tolerance limits as very coarse (v), coarse (c), medium (m), and fine (f). These tolerances specify standard tolerances for 4 different classes based on their range for a part dimension. General tolerances may be defined for linear or angular measurements, as well as for chamfers or other rounded parts. The various types of tolerances applicable to machined parts are: General Tolerances When we do this, it ensures that the components fit well in an assembly and work as expected. We usually define it for only those features in a part that mate with other parts. This has a rather opposite effect actually because adding requirements to each measurement will make for a very costly part. This ensures customer satisfaction and reduces retooling costs for the CNC machine shop, should anything not accord to the requirements.īy appropriate features, we mean that it is not necessary to define tolerance for every dimension. Thus, it is in the designer’s interest to define part tolerances for the appropriate features before handing it over for CNC machining.

Unless the customer specifies any certain tolerances, the parts will usually be made according to a general tolerance grade. Common Tolerances in CNC MachiningĮngineering tolerances are a necessary requirement when defining product measurements. For the remaining cases where small dimension variations can affect the part’s performance, tighter tolerances can be maintained. The standard tolerance limit is a small number and in most cases, such a small difference between two parts that perform the same function may not even matter. For reference, the thickness of a human hair is 0.002” (0.05 mm). The tolerance limit defines the maximum allowable difference between corresponding dimensions of the two parts.įor CNC machining, the standard tolerance limit is set around +/-.005” (0.127 mm). This difference in final measurements between two parts made from the same CNC machine is accounted for by setting up a standard tolerance limit. It is impossible to create identical parts of the same exact dimensions no matter which CNC machine we select.

The final measurements between any two parts made using the same manufacturing process even on the same CNC machine are always off by a small amount. While CNC machining services are highly accurate when it comes to product dimensions, they are not perfect.

0 kommentar(er)

0 kommentar(er)